News Flash

15.Aug.2019

Min Chun Precision-International Aerospace Supply Chain Rising Star

Min Chun precision specially introduces German high-precision production equipment, for example, DMG five-axis processing machine, milling-turning compound, turning-milling compound machine to achieve high-precision and high-efficiency processing mode, and improve production efficiency. Image/provided by the industry.

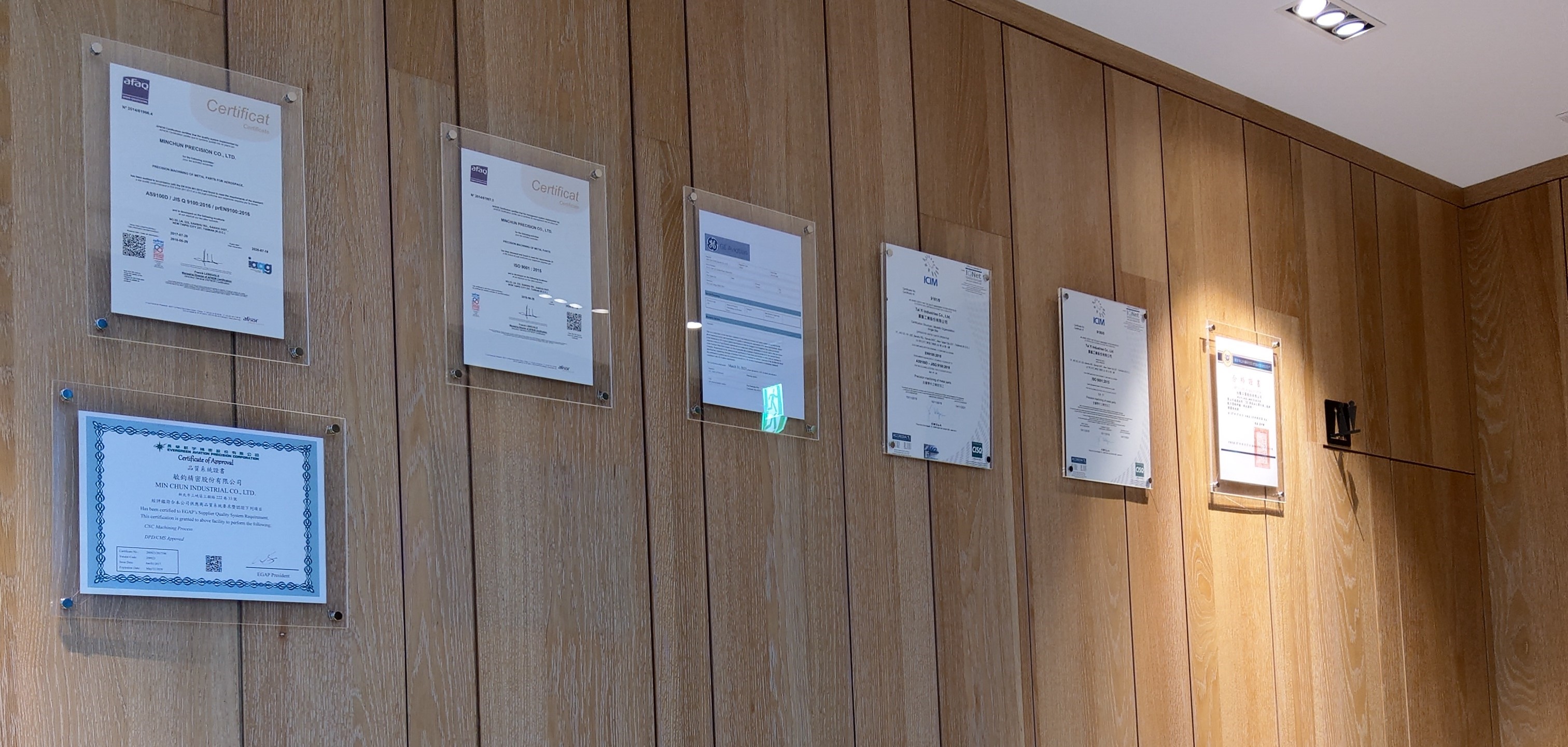

Min Chun Precision is located in the 1,000-square-meter factory in Sanxia, New Taipei City. The specifications of the factory are in accordance with the requirements of aerospace manufacturing process, and it has ISO 9001 international certification, AS9100 international aerospace certification and other certifications. Photo / Lin Yizhen

Min Chun Precision Co., Ltd. is a professional manufacturer of aerospace components. In order to open up its international market reputation, it participated in the biennial "2019 Taipei International Aerospace and Defense Industry Exhibition" for the first time this year. As a major supplier of advanced jet trainer, Minjun will showcase high-end aerospace key component technology and prove itself as the only manufacturer in Taiwan that has introduced German high-precision DMG five-axis machining machines, so that customers can clearly understand how Min Chun The product quality is impeccable and attempt to demonstrate the ambition to become a global supplier of key components.

Min Chun Precision (formerly Min Chun Industry) was established in 1985 and changed its name in 2014 to transform into the aerospace industry. Optimistic about the next 20 years, the global demand for aircraft will rise sharply to more than 42,000 aircraft, and the total output value will reach as high as 6.3 trillion US dollars. Min Chun built a 1,000-square-meter factory in Sanxia, New Taipei City in 2017. The specifications of the factory are in accordance with the requirements of aerospace manufacturing process, and obtained ISO 9001 international certification and AS9100 international aerospace certification. It was officially put into production in May 2018. In the same year, it obtained the qualification of qualified supplier of Hanxiang Airlines and was selected as the excellent manufacturer of Hanxiang. Parts, communication equipment, auto parts, and various hydraulic component assemblies.

敏鈞總經理洪一鈞表示,成立之初就誓言要做國際航太重要供應鏈,因此公司走向及策略以承製航太零組件為公司核心業務,並以航太管理制度及品質要求(AS9100)延生相關精密零組件加工,如光學零件,通訊零件,微波零件,人體醫療部件。為因應歐美先進的生產技術,生產採用高精度的五軸銑車複合加工機,讓生產製造更加有效率,用價值提升取代壓低成本,為了避免組織僵化,管理「扁平化」,3階段管理,簡化流程,提升作業效率。透過組織作業改善,將複雜的工作簡單化,並且將所有的專案執行依據作業流程實現,有效地將工作順利完成,且使得在此工作的同仁可以有一個作業指導可以遵守,並且將每個產品及專案「均質」完成。

軟實力的提升外,敏鈞在硬實力的努力也不容小覷。生產設備特別引進德國高精度DMG五軸加工機,銑車複合,車銑複合機種以達成高精度及高效率的加工模式,另外傳統三軸與立式車床亦可依照生產模式搭配並排除生產瓶頸,徹底降低因為換線或是治具更換產生的時間耗費。為因應先進五軸製程,還搭配德國首選cad/cam軟體-hypermill,以數位模擬及預先規劃的模式,取代傳統手打程式並執行研發及生產製造,有效提升產品研發效率及製造數位化。

洪一鈞強調,公司向來重視產品品質,對於「唯有將品質做好,企業才有生存的利基」,公司同仁都有共識。因此控管透過三不一做好的品質政策下,「不生產不合格產品」、「不接收不合格產品」、「不流出不合格產品」、「1次就好」。讓所有在本公司生產的產品零件都可以擁有完整的追溯及一致的品質要求,創造高優質產品。此外,為加強公司與國際接軌,本公司通過AS9100國際航太認證並採用國際知名品檢設備BROWN&SHARP高精度三次元量床。透過首件承認制度,自主檢驗,製程巡檢與成品檢驗有效確保產品可以符合客戶規格要求。